How China's small towns meet global demand

When you lie on the beach, soaking up the sunshine and relishing warm breeze, there is at least a 25-percent chance that your swimsuit was made in Huludao, an obscure city shaped like a gourd in northeast China.

In the production workshop of Yifeng Group, a local private swimsuit maker, pieces of blue fabric are hung on the production line, waiting to undergo a 20-plus step process including cutting and sewing before being packaged and shipped to Britain.

"It is a peak production season. Our factory is running at full capacity," said 61-year-old Liu Xueyan, the chairwoman of the company.

There are more than 1,200 swimsuit making companies like Yifeng in Huludao, whose combined annual output exceeds 14 billion yuan (around 2 billion U.S. dollars).

The city in Liaoning Province produced 190 million swimsuits last year, accounting for 25 percent of the global market and 40 percent of the domestic market, local swimsuit industry experts estimated.

A worker makes bikini at a workshop of a sportswear company in Huludao City, northeast China's Liaoning Province, March 6, 2019. (Xinhua/Pan Yulong)

MAKING A SPLASH

The swimwear industry in Huludao took off in the early 1980s, thanks to the country's reform and opening up. Every summer, tourists wearing various swimsuits swarmed into the city's seaside for vacation. Local people sensed the business opportunities.

"Many villagers had experience in garment processing, so it was not difficult to make swimsuits with simple designs," said Yu Shuqin, vice president of the Swimwear Industry Association in Xincheng, a production hub of swimsuits and a county-level city administered by Huludao.

Liu is one of the earliest pioneers. When she worked as a civil servant in the local forestry bureau, she usually made swimsuits at night to earn extra money -- six yuan a night, three times that of a civil servant's daily wage.

She quit her stable job and started her own business in 1993. "My husband and I promoted our swimsuits in cities like Beijing, Shenyang and Dalian. They were quickly sold out by beach peddlers at first," Liu recalled. Later, they moved up the ladder by selling their products in big shopping malls.

Over the years, the number of workers in Liu's factory has increased from dozens to more than 500, and 20-plus sewing machines have been replaced by an advanced production line, with an annual capacity of over 10 million swimsuits.

"Family workshops once dominated swimsuit making in Huludao. Compared with the city's traditional strengths in petroleum, nonferrous metals and shipbuilding, they were looked down upon by many people," said Shi Wenguang, a former vice mayor of Huludao who played an important role in developing the local swimsuit industry.

The swimwear business stood out as the local government was keen to adjust the city's industrial structure and reduce its heavy reliance on traditional industries.

To create a solid brand image, Huludao has hosted an international beach swimwear culture expo every year since 2011.

"Through the expo, we hope to attract more talent and turn their fancy designs into products. Anyway, the final competition in the swimwear industry depends on designers' creativity and brand connotation," Shi said.

To diversify market channels, the city has seized new opportunities such as e-commerce.

The highlight of Peng Wei's day is to check the sales of his swimsuits on Amazon.com, a global online shopping platform.

"Not bad, 10 types of our products were listed on the top 100 best-selling swimsuits last month on Amazon," said 37-year-old Peng, general manager of Geman Swimwear Co., Ltd. in Xingcheng.

Now Huludao is home to over 35,000 swimsuit e-commerce enterprises. Through the global retail platforms such as AliExpress and Amazon, Made-in-Huludao swimsuits have been exported to over 140 countries and regions including the United States, Germany and Australia.

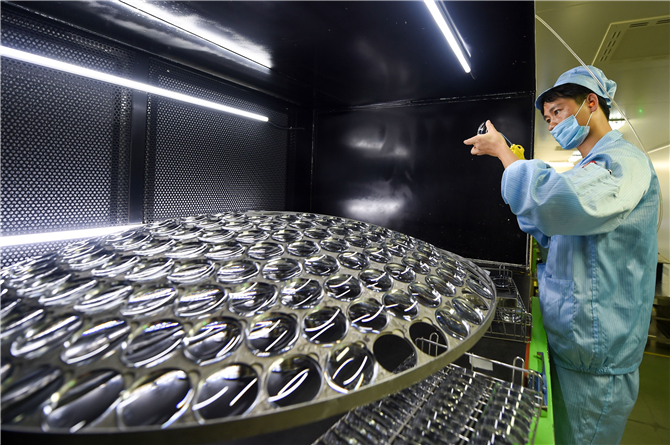

A technician arranges the strings of a piano at a piano company in Yingkou City, northeast China's Liaoning Province. (Xinhua)

UP FOR GRABS

Indeed, a growing number of small cities and towns in China are well-positioned to benefit from characteristic industries ranging from bikinis to guitars and eyeglasses.

Residents of Zheng'an, a county deep in a valley of southwest China's Guizhou Province, used to make a living by being a farmer or a migrant worker. Now they have found a new way out -- making guitars.

Zheng'an is now home to some 54 guitar-related enterprises. Six out of 10 global guitar brands have manufacturing plants in a local industrial zone. Around 60 percent of products there are exported to more than 30 countries and regions.

In Danyang, east China's Jiangsu Province, rows of glasses shops remind visitors that they are in the beating heart of the world's production hub for spectacles. There are more than 1,600 companies and around 50,000 people engaged in the eyewear industry.

A worker adds film onto glasses at a glasses company in Danyang City, east China's Jiangsu Province, July 12, 2018. (Xinhua/Li Bo)

"Since the reform and opening up, a growing number of Chinese workers, farmers and craftsmen have started their own businesses, overcoming difficulties including fund shortage, and successfully turning small workshops into big private companies," said Zhang Wanqiang, an economist with the Liaoning Provincial Academy of Social Sciences.

Zhang considered the industrial cluster as an important way to enhance China's micro-economic competitiveness and the growth of the private sector which contributes more than 60 percent of GDP and 80 percent of urban employment.

With unique pillar industries, Chinese small cities and towns aim to go further. They are seeking industrial upgrading and exploring new ways to gain high-quality growth.

Facing the increasingly fierce competition and the urgent need of self-development, Huludao is also undergoing transformation.

"We use big data to analyze consumer preferences, innovate in business models and extend the industry chain to beat the competition and become a leader in the industry," said Wang Na, chairwoman of Xingcheng Yinghua Swimming Clothing Co., Ltd.

Editor: John Li