Roaring Chinese factories in full swing to stabilize global supply chain

As China's caseload of COVID-19 continues to wane thanks to strict control measures, factories across the country have gradually returned to normalcy, which is expected to mitigate the impact of coronavirus on the global supply chain.

Aerial photo taken on March 17, 2020 shows chartered buses with migrant workers passing a toll station in Xiaogan, central China's Hubei Province. (Xinhua/Hu Huhu)

With work and production resumption accelerating in China amid further containment of the disease, the upstream and downstream of the industrial chain is gradually linking up again, said Wu Hongliang, an official with the National Development and Reform Commission.

"The overall advantages of China's industrial chain have not changed despite the outbreak," Wu said.

ROAR BACK INTO LIFE

In the city of Ningbo in east China's Zhejiang Province, Shenzhou International Group Holdings Limited, a giant knitting manufacturer whose annual orders with world-renowned brands such as UNIQLO, Adidas and Nike exceed more than 20 billion yuan (about 2.82 billion U.S. dollars), has seen its work resumption rate reach 95 percent so far.

"We've adopted a grid-based approach, taking one floor as an independent and closed unit," said Chen Zhongjing, executive deputy general manager of the company, adding that such an approach can ensure the risk of an outbreak is controllable.

"Nothing would be possible without the help of the local authorities," said Ma Jianrong, chairman of the company with about 30,000 employees from 14 Chinese provinces and cities. "The municipal government has coordinated 700 buses to bring our migrant workers back to work."

In China, the government and companies are beefing up efforts to help stabilize global supply chain, working together to revive business activities while implementing strict prevention and control measures to prevent any resurgence in cases.

NanoFilm Vacuum Coating (Shanghai) Co., Ltd., with its production operations in Shanghai's Qingpu District, carries out vacuum coating for products including consumer electronics, automotive and precision engineering parts, serving as a key link in the supply chains of some global multinational technology companies.

"More than 1,500 mask-clad workers have returned to work in our Qingpu factory, and the Shanghai government has given us strong and much-needed help," said Dr. Shi Xu, executive chairman of the company.

"As most of the workers are from cities outside Shanghai, local authorities have helped to arrange hotel accommodation for their 14-day quarantine, providing considerate services to ensure our healthy staff can return to work as soon as possible," he added.

Workers are seen at a factory of the SAIC Motor in Pudong New District of Shanghai, east China, Feb. 27, 2020. (Xinhua/Ding Ting)

To revive the whole automobile industrial chain, the Shanghai Municipal Commission of Economy and Information has facilitated the work and production resumption of eight large-scale complete vehicle enterprises and more than 600 auto parts manufacturers.

With their support, eight suppliers in the upstream and downstream industrial chains of Tesla's Shanghai gigafactory have resumed operations.

PLUG TO GLOBAL SUPPLY CHAIN

With the hum of machinery filling the air, CRRC Zhuzhou Locomotive Co., Ltd. (CRRC ZELC) resumed production on Feb. 11 to keep its supplies available to its overseas projects. About 95 percent of its employees have now returned to work.

Ding Ci, technical manager of the company's India's unit, said the Chinese headquarters is working diligently to ensure a continuous supply of parts, "dispelling our Indian partners' worries about the impact of the epidemic."

"All work is proceeding as normal," Ding said.

It is widely believed that the virus outbreak is a stress test for China's resilience in the global supply chain, said Vinoth Kumar, an electrical technician with CRRC ZELC's India unit, working on a metro project in the Indian city of Mumbai.

"In the case of the Mumbai metro project, I am 100 percent confident in the supply of trains from CRRC ZELC in China," Kumar said.

Shortly before the World Health Organization declared the outbreak as a pandemic, China's State Council unveiled new measures to support foreign trade and investment in case the increasingly severe situations overseas further weigh down global industrial chains.

The measures in the pipeline include a shorter negative list of foreign investment and more foreign trade loans from financial institutions.

Foreign trade of northeast China's Heilongjiang Province climbed 9.3 percent year on year to 32.28 billion yuan in the first two months of this year.

According to local customs, the northernmost province's import and export values with its neighbor and major trade partner Russia registered a 14 percent year-on-year growth during the period to 22.97 billion yuan.

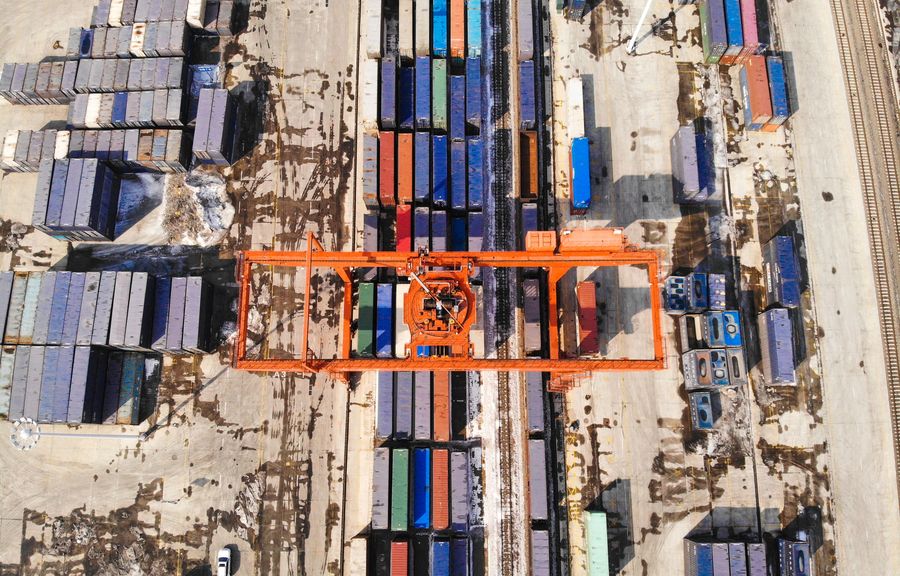

Aerial photo taken on March 19, 2020 shows the Harbin international container center in Harbin, capital of northeast China's Heilongjiang Province. (Xinhua/Wang Song)

Nearly all major foreign trade firms in 19 provincial regions, including Zhejiang and Jiangsu provinces and Shanghai, have resumed production, Li Xingqian, director of the foreign trade department under the Ministry of Commerce, told an online news briefing on March 12.

"In the short run, the impact (of COVID-19) on the global economy and supply chains is unavoidable," Li said, adding that China will work to intensify global cooperation to contain the COVID-19 outbreak, and minimize its impact on both China's foreign trade and global trade growth.

Editor: John Li