What’s New in 2024 | Cracking the mystery of carbon neutral milk

In order to embrace this year’s Two Sessions of China, we have recently launched a new report series named “What’s New in 2024”. Led by Htike Lwin Ko, our host from Myanmar, we are about the take a special journey to the forefront of some newly-emerged industries and uncover what truly sets them apart in the refreshing spring breeze.

Cracking the mystery of carbon neutral milk

Time: March 1, Morning

Place: Yunnan Yili Dairy Co., Ltd, Yanglin Economic and Technological Development Zone, Songming County, Kunming, China

Weather: Clear and Sunny

“Newness” Content: 100%

Today, I am going to enjoy a bottle of milk.

My Chinese colleagues tell me that this bottle of milk is produced in the first carbon neutral factory in the entire Chinese food industry.

How unique can a bottle of milk be? The image in my mind of a milk factory involves continuous assembly lines bustling with workers milking cows, packaging the milk, and eventually the milk making its way to us in cartons.

However, when I arrival at the factory, I realized that it is very special.

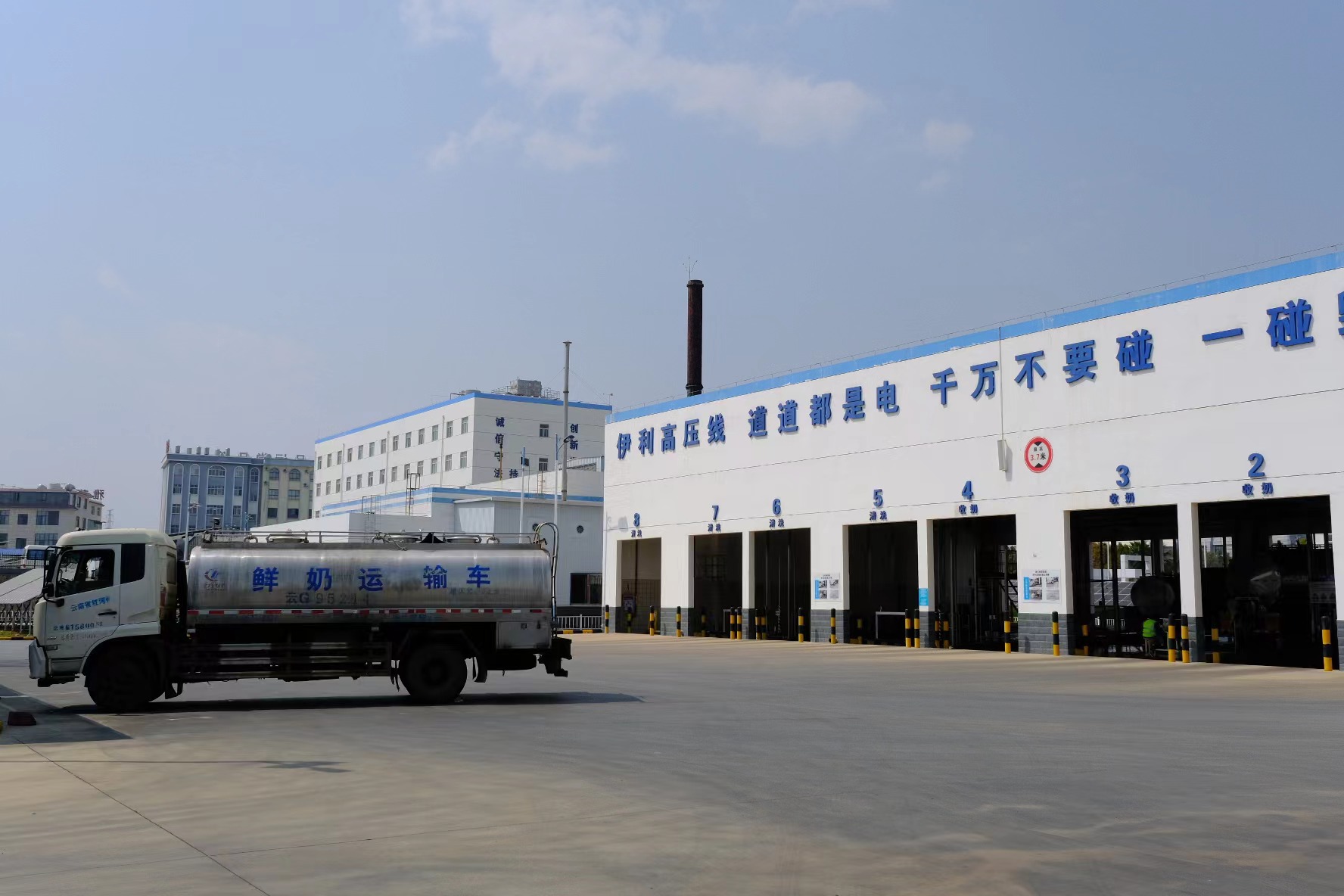

The Yunnan Yili factory. (Zhang Ruogu/Yunnan Daily)

“The trash bin has a story to tell!”

“I’m curious to see what sets the carbon neutral factory apart from other factories.” When I asked about this, a staff, surprisingly, took me to a trash bin.

The words “This bin is crafted from recycled milk cartons” unveiled its unique characteristics. Over a thousand milk cartons that were previously discarded have been recycled and repurposed into an eco-friendly bin, which are now prevalent throughout the Yunnan Yili factory.

The photovoltaic cells on the rooftops and car sheds of the factory glisten in the sunlight; the ongoing conversion of natural gas boilers to decrease emissions and the use of water-source heat pumps showcase the factory’s commitment to sustainability. Moreover, the meticulously upgraded sewage treatment system has resulted in discharged water so clean that it can support aquatic life. Furthermore, the packaging carton manufacturers and straw factories upstream and downstream of the milk factory are actively reducing emissions and enhancing their integration within the industrial chain...

I think I’ve found some secretes about this carbon neutral factory.

The photovoltaic cells of the factory glisten in the sunlight. (Zhang Ruogu/Yunnan Daily)

“I can see neither milk nor people”

My interview ran into a “hiccup”!

In the workshops and production lines, there was a noticeable absence of milk and individuals. The machines on the nine production lines in the workshop were operating with precision and at a rapid pace. Throughout the entire production process at the milk factory, not a single drop of milk was visible. “See, within the completely sealed and sterile storage tanks and pipelines, all production tasks have been finished.”

Pre-processing, filling, conveying, straw pasting, palletizing, packaging, and leaving the warehouse... A bottle of milk was swiftly produced at a breathtaking speed. Only at a few crucial stages, there were several workers in aseptic suits overseeing the production. The factory manager explained that the packaging workshop is equipped with robots, with each robot capable of handling palletizing tasks for two high-speed assembly lines simultaneously. It appears that automation and intelligence have significantly enhanced production efficiency, minimized energy usage, and ensured a commitment to “zero carbon.”

I believe I have glimpsed a more extraordinary fact behind the carbon neutral milk, which is innovation.

The production line of the Yunnan Yili factory. (Zhang Ruogu/Yunnan Daily)

“Cow’ houses are very cozy!”

Time: March 1, Afternoon

Place: Youran Dairy’s Xundian Ranch in Yunnan Province owned by Yili Group

Weather: Sunny and Warm

“Newness” Content: 1,600 percent

The dairy industry’s production chain encompasses the primary, secondary, and tertiary sectors, requiring a wealth of expertise to achieve “zero carbon,” “low carbon,” and “carbon neutral” standards across the extensive production process. After this morning’s factory tour, my curiosity piqued, leading me to venture into the ranch where the milk originates.

“How can we overcome the notion of cows being big methane emitters?” “Well, ensuring the cows have a balanced diet is key. What is on their ‘dinner plate’ makes a significant difference.” Upon my arrival at the ranch, the ranch manager introduced me to the 1,600 cows living there. Going above and beyond, he even guided me through the cows’ feeding area.

Under the radiant sun, long and neat cowsheds are lined up, housing thousands of cows leisurely grazing in a spacious and well-lit environment. The seemingly ordinary forage is actually a meticulously crafted blend containing alfalfa, silage, concentrate feed, fescue, imported oats, along with salt and various trace elements. These low carbon feeds, developed through advanced rumen technology, not only enhance the cows’ feed absorption and utilization but also decrease methane emissions from their intestines. Reduced cow “emissions” lead to lower carbon emissions overall, especially when combined with selective breeding to pass on the “low carbon” gene to future generations.

Apart from the “nutrition canteen,” I found myself intrigued by the cows’ living quarters. The cows roam contentedly in the shed, enjoy a break in their cozy individual “bedrooms,” and engage in exercise in the designated area... After visiting the cow houses, I genuinely feel their places are very cozy.

“Raising a cow is no simple task!” After trekking across the mountains to visit the cows, I made this observation, eliciting laughter from the ranch manager. He told me that at Youran Dairy, a team of 23 doctoral degree holders and over 30 scholars who have returned from the United States collaboratively research dairy farming technology, developing over 650 standardized, replicable, and scalable dairy farming procedures. It dawned on me that the ranch not only excels in innovation but also in academic expertise, with a great number of staff having doctoral degrees.

As a day of exploration came to a close, I stood at Xundian Ranch and surveyed the scene. The setting sun cast a golden glow upon the mountains, gently illuminating the cows. It was a glimpse into the serene life of the cows, reflecting the essence of our own well-being.

As my visit came to an end, a manager of Yili Group in Yunnan shared exciting news with me: they are set to introduce a new avocado-flavored yogurt product in March of this year. I am eagerly looking forward to trying it!

Youran Dairy’s Xundian Ranch in Yunnan Province owned by Yili Group. (Zhang Ruogu/Yunnan Daily)

Planning:Xiongyan, Chu Donghua, Zhang Ruogu

Reporters: Han Chengyuan, Zhang Ruogu, Huang Yixian

Photographers: Zhang Ruogu

Video maker: Li Wenjun

Host: Htike Lwin Ko

Translator (video): Wang Jingzhong